Laying patterns

All our floors are manufactured to custom needs

Oak Flooring

- Designed to suit individual needs Your imagination is the limit. Our craftsmen will satisfy even the most demanding customers. We manufacture and deliver our products according to customer needs and specifications. Human creativity only enhances nature's design.

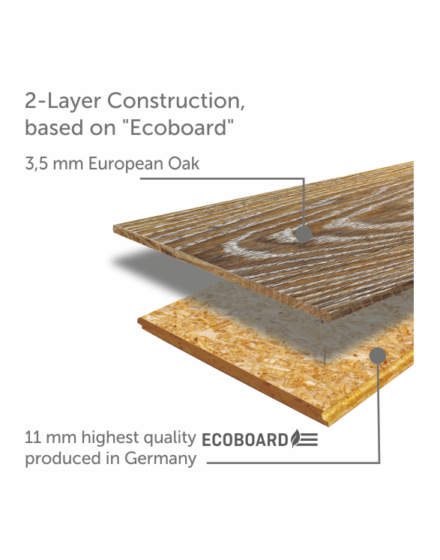

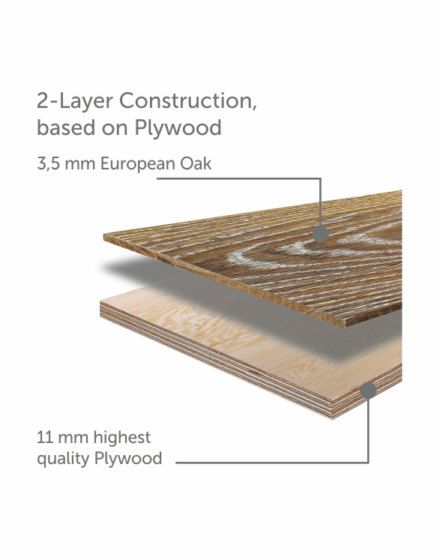

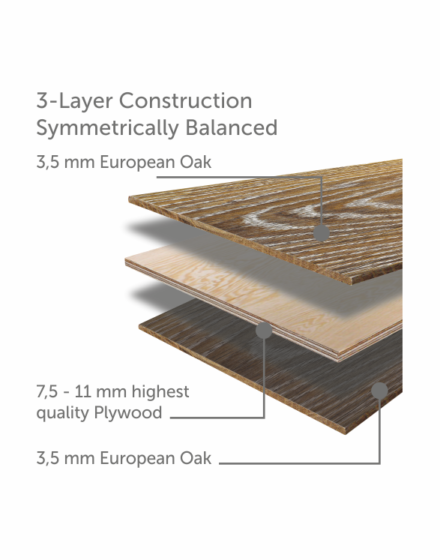

- Ideal for underfloor heating Oakwood is a type of hardwood which is durable and have better thermal conductivity. We manufacture two-layer and three-layer engineered oak planks which offer maximum stability and are ideal for underfloor heating.

- Highest quality We carefully control the entire supply chain: from wood selection, shipping and precise technological cycle of wood preparation to manufacturing, professional installation and warranty. Our prices are among the most competitive in the market.